Internet of things in Manufacturing

We are familiar with the Internet of Things (IOT) by now. But if you aren’t using the IoT’s infrastructure at your work place, epsilon electronics is here to provide broad-gauge information about all the products and services. With the number of networked sensors increasing across production, supply chains and products, we are starts to tap into a system that enables real-time, automatic interactions between systems. For gain productivity improvements and expose new ways of improving manufacturing and supply chain operations, businesses make use of digital transformation.

IoT Data Analysis

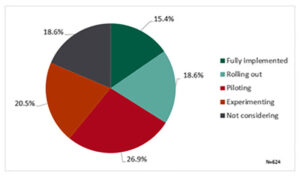

APQC has congregated and analyzed information from 626 global organizations about manufacturing practices, focusing on digitalization and the adoption of emerging technologies. One main direction of examination is the use of the Internet of Things (IoT) in manufacturing.

In APQC’s analysis, using IoT for predictive asset maintenance and condition monitoring is fully executed in only 15 percent of organizations. A bit larger group (almost 19 percent) is currently rolling it out, and 27 percent is in pilot mode. This graph focuses on the benefits respondents anticipate from digitalization and automation in electronic industry.

Role of IOT in Manufacturing

Essentially, IOT plays two different roles in manufacturing. IOT can connect the ‘things’ that make your product machine and equipment- manufacturing processes run smoothly. In this, sensors and ADC has played important role. Using these devices, we can collect or generate data of smart products. This data is used for business analytics, but how effectively it is extracted for tactical insights and verdict remains to be seen. Data is frequently used for strategic type of decision made with operational scheduling and management systems. Warehouse management systems are a particular type of these operational solutions.  The motto of this is, the more these solutions are connected, the more data is available and it will very much helpful to provide real-time data for decisions that can directly collision the quality and quality of production. And connecting to the asset management, it can directly collision the efficiency and utilization of product and equipment by optimizing maintenance.

The motto of this is, the more these solutions are connected, the more data is available and it will very much helpful to provide real-time data for decisions that can directly collision the quality and quality of production. And connecting to the asset management, it can directly collision the efficiency and utilization of product and equipment by optimizing maintenance.

Use Cases

Now days, stronger dictate for customization, enhances customer expectation and the convolution of the global supply chain – these challenges inspire manufacturers to find new, more futuristic ways. In manufacturing operations, epsilon electronics invented many cases which involve several assets and operation personnel. The complication and depth of manufacturing shows in the numerous IoT use cases in manufacturing.

Operations Remote monitoring & controlling of the heat treatment process plant via IoT Sensors and Cloud platform. This helps customer to reduce manpower working hours, improve the process cycle timing, and get real-time status of an ongoing process.

Monitoring Remote monitoring of temperature and humidity of food storage plant via IoT sensors and cloud platform. This helps customer to get insights about the status of food conditions under different environments

There are several other manufacturing IoT use cases on levels of controlling-monitoring, processes and people which includes safety, security, employee protection and productivity, and many other links between manufacturing who is connected with services or industries – these all are contribute to the vast IoT related manufacturing solutions.

In addition to this, vehicle and asset tracking connected workshop applications, employee safety applications, health monitoring, air quality management, smart measurement applications (depending on the type of materials), asset protection, risk management and so on. But, there are some related processes like production assets which are used for shipment, packaging and quality control of manufactured goods another.

Technologies are used in IOT

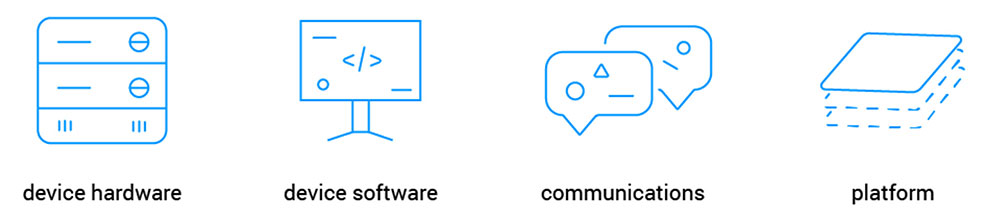

We have break down the IoT technology stack into four basic technology layers which involved in making the Internet of things work. These are the following:

Depending on the defining of a given IoT use cases, each communications may offer different services between power consumption, range and bandwidth. For example, if you’re pile a smart home, you may want to have your indoor temperature sensors and heating controller integrated with your smart phone so that you can remotely monitor the temperatures in each room and adjust it in real-time according to the current needs.

Summary

IOT in manufacturing has made itself comfortable in our house, public spaces, offices and Industries. But somehow it’s failing due to lack of knowledge and contact to the technology, are reason for the some issues. Epsilon electronics has an expertise among all the IOT solutions providers. Therefore, if you are looking for the IOT services contact us at info@epsilonelectronics.in